Label control

Project description

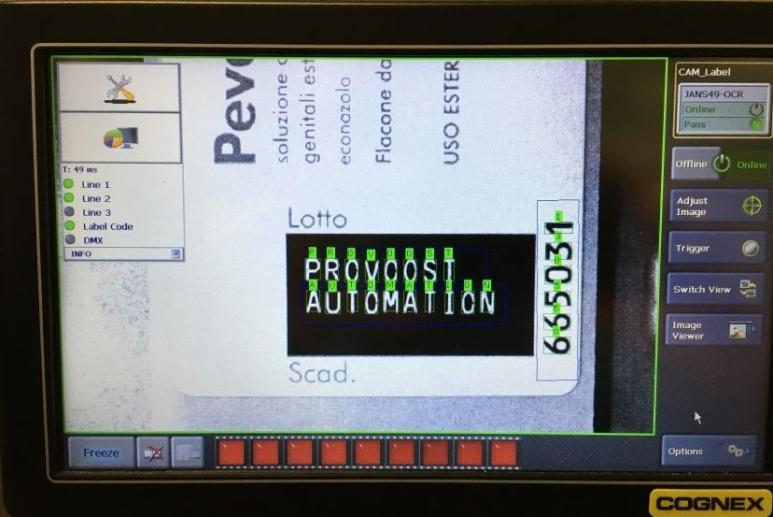

For Janssen Pharmaceutica, we developed vision systems for label control of packaging. This involves checking that the correct labels are printed with the correct code. Each label undergoes a label check in a few milliseconds to ensure that each bottle is provided with the correct label.

The vision system for label control of bottles begins with label printing. Using a laser, the lot number and expiration date are printed on the label. Next, the vision system places the label in front of a camera, which automatically takes an image. Then the vision system begins the actual label check.

The camera first checks the code on the label to ensure that the correct labels are placed on the correct product. If the code is correct, the camera searches for the lasered data in the black box. If three lines are lasered, the camera checks all three. If two lines have been lasered, the camera will check to make sure a third line has not been lasered.

Once the vision system has performed the label check and the camera approves everything, the machine receives a positive signal. The bottle will then proceed to be further packaged. Read here for more information.

Do you also want an automated solution for your production process?

Contact our experts and get honest advice.Do you also want an automated solution for your production process?

Contact our experts and get honest advice.