Monitoring packaging and products with cameras

How does packaging control work?

Your products must leave for customers in complete order. A vision system automatically checks all packaging. What your camera needs to check, you decide. Size, bar code, damage. Need help?

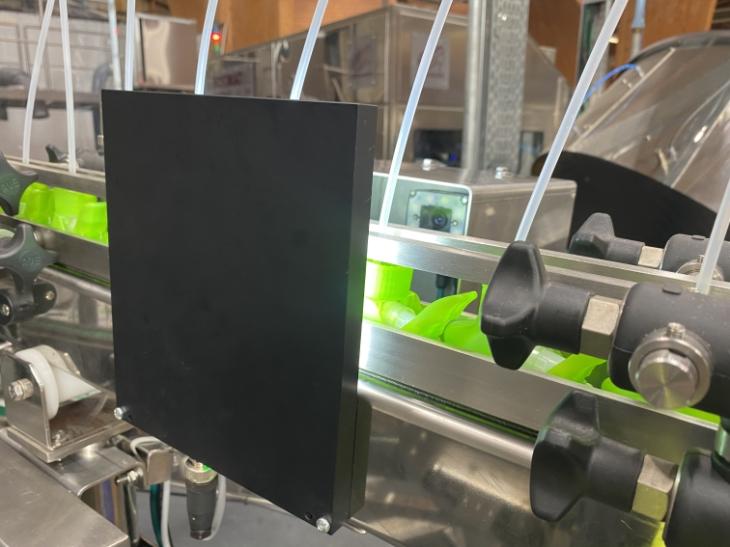

Control of packaging and labels by cameras

The most common forms of camera inspection are packaging inspection and label inspection.

- Is the packaging damaged or folded incorrectly?

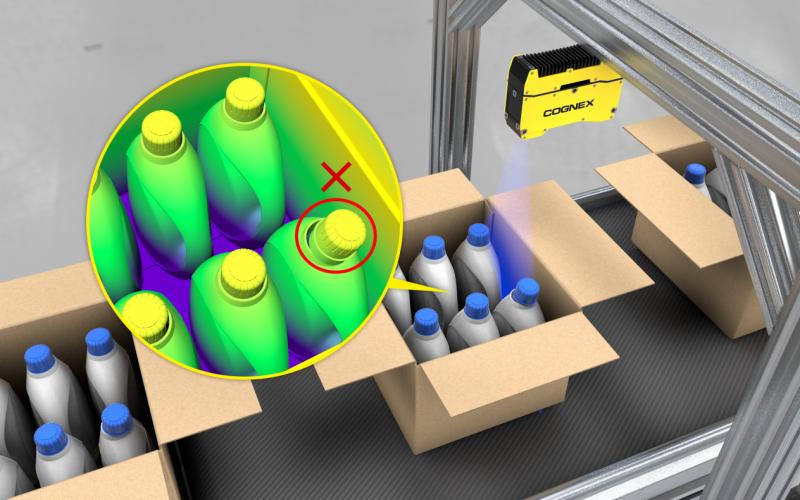

- Are there enough bottles in the package?

- Is the barcode on the label in order?

- ...

Everything is checked very carefully. So you can rest assured that you are only selling products that are 100% in order.

Check your packaging both 2D and 3D

Did you know that there is a difference between packaging control in 2D and 3D?

- 2D control: the camera looks at images, sizes or labels on your packages

- 3D control: the camera also looks at the shape or volume of the package

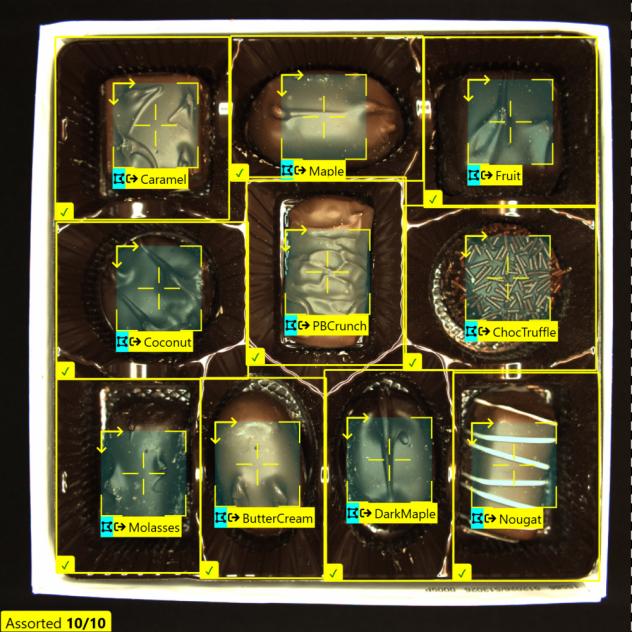

You can even go beyond just looking at the packaging. You can also check the products themselves.

- Is the product big enough?

- Is there enough filling in a cookie?

- Has the silicone adhesive been applied correctly?

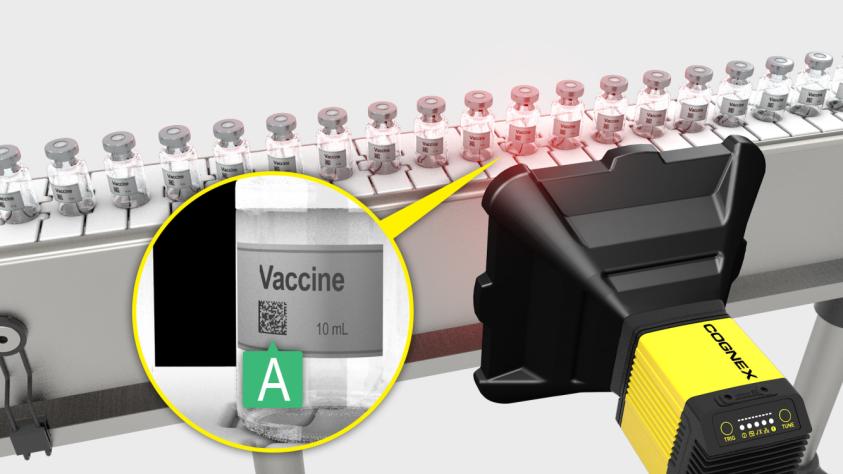

Built-in smart camera for packaging control

Very often we integrate a vision system with built-in smart camera. This camera can monitor anything you want:

- Is the data present?

- Does the label stick straight?

- Are the colors correct?

- Is the packaging undamaged?

In packaging control, codes are especially popular, especially in the pharmaceutical and food sectors. Mandatory and correct data are extremely important here. A smart camera ensures that every package goes out correctly.

Other expertise within vision systems

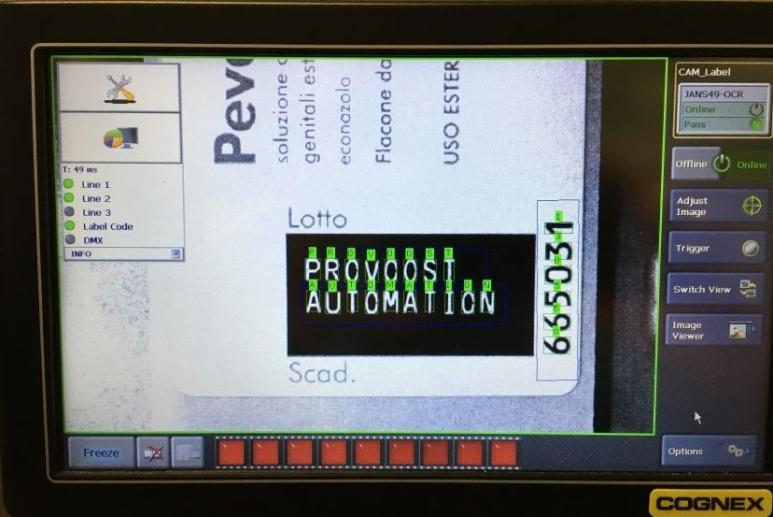

Control printed data

The camera detects presence and correctness of printed, mandatory data.

Locating products

A camera looks for products on the conveyor belt. Then the robot can reposition them, move them, ...

Machine Vision

The umbrella term for vision systems. Locating, monitoring, measuring ...

ID Reading/barcode scanning

Cognex scanners that can read and interpret barcode data.

Creating the future together.

Interested in optimizing your production process with us?

Make a no-obligation appointment to discuss your needs and expectations. The experts at Promation will always provide you with honest advice.