Why Promation wants to be the safest cobot integrator in Europe

Let’s begin with a confronting fact: around 80% of all cobots in Europe are currently installed unsafely. That’s not our opinion, it comes from independent inspection bodies that evaluate systems daily.

Yet many integrators treat the safety standard as if it were optional. A suggestion. A guideline. Something you “keep in mind.” But safety doesn’t work that way and someone needs to take a clear, uncompromising stance.

That’s why Promation deliberately chooses to position itself as the safest cobot integrator in Europe. Not because it’s the easiest path, but because it’s the only responsible one if you believe in the future of cobots.

Why safety must come first

One poorly integrated cobot causing an accident is enough to make people believe that all cobots are unsafe. That belief is not only incorrect, it threatens the credibility of the entire industry.

Cobots can be extremely safe, but only when the application is properly engineered, measured and validated. That’s why we often say: “There are no collaborative robots. There are collaborative applications.”

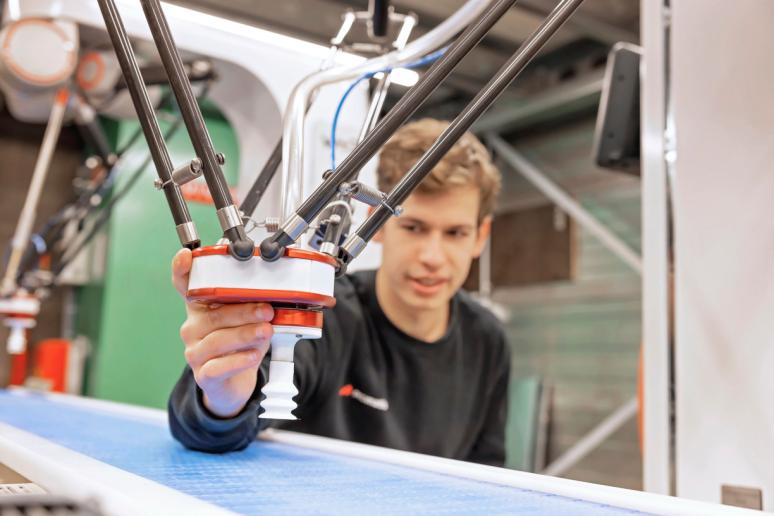

Safety depends on the entire combination: robot + gripper + product + speed + motion + environment. And this cannot be judged visually, it must be measured.

Example: multinational visits Promation after recommendation by their inspection body

A major multinational recently visited our facility to see a cobot installation. Not because we install the most cobots in Belgium, they came because their independent inspection organisation literally told them: “If you want to see cobots integrated correctly and safely, you need to go to Promation.”

This is perhaps the highest form of recognition an integrator can receive: not because we say we are safe, but because an independent party — with nothing to gain — confirms it.

This is exactly why we continue to build on this approach: safety must be measurable, provable and independently validated.

How we measure safety

Method 1: Pressure testing

Pressure testing is the only official method to certify collaborative applications as safe, because it is performed strictly according to the robot standard.

Why?

- The standard specifies maximum allowable force for every part of the human body

- Only a pressure test can objectively confirm that these limits are respected

- Without measurements, any safety claim is guesswork

Because no commercial test systems exist, we designed and built our own complete pressure-testing unit in full compliance with the standard. We use this system to measure:

- gripper forces

- impact forces

- emergency situations

- corners and edges

- product safety

- speeds

- trajectories

Only when the complete application remains within all limits can it be classified as truly collaborative.

Method 2: Independent inspection

While many integrators rarely involve an external inspector, we do so almost every time. We work globally for clients who consider safety their highest priority. A single unsafe installation can:

- harm our reputation

- harm the reputation of cobots

- damage trust in automation

That’s why all our work is validated by independent organisations, giving customers complete certainty.

Why cobots require more attention than industrial robots

For an industrial robot, safety is often straightforward:

- Place it in a safety cage

- Calculate the required distance

- Finished

Cobots require far more evaluation:

- Is the gripper safe by design?

- Is the product safe to handle?

- What is the motion path?

- Are there sharp edges?

- What speeds and accelerations are used?

- How far does the arm reach into human space?

- What happens if someone unexpectedly enters the zone?

- Do all forces stay below the limits at every point?

These combined factors determine whether an application is safe. That is why our team goes exceptionally far in measuring and validating.

Why companies appreciate our approach

Manufacturers want reliability, flexibility and maximised safety. Cobots can offer all of this, but only if integrated by specialists. Our customers know that we never deliver a system without:

- pressure testing

- independent validation

- complete measurement reports

- documentation compliant with the standard

- a full risk assessment

This explains why major companies — often on advice from inspection bodies — are choosing Promation.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Conclusion: Cobots are safe, but only when the integrator is too.

Cobots offer tremendous benefits, but their reputation depends entirely on the quality of integration.That is why Promation aims to be the safest cobot integrator in Europe. Not to claim a title, but to set a standard and to make safety objective and measurable.