Why Cognex vision systems are a smart investment for every production environment

Many manufacturing companies still rely on manual quality control. Tired eyes, barcodes that pass just a bit too fast or labels that go unnoticed. Sound familiar? You’re not alone. But why keep depending on human error when smart technologies like Cognex vision systems are available?

At Promation, we believe that automation is not a goal in itself, but a tool to help you produce better. And one of the most underestimated, yet powerful, tools is the vision system. Especially when it’s from Cognex.

In this blog, we’ll explain what machine vision is, how it benefits your operations, and highlight three top performers from the Cognex range: the IS2800, IS3800, and IS8900.

What is a vision system?

A vision system is a smart camera with a brain. It sees, analyzes, and makes decisions in real-time. That might mean checking if the correct date is printed on a package, if a label is properly applied, or counting, positioning, or sorting products, all without human intervention.

And because it’s automated, you get consistent quality, 24/7. No fatigue, no mistakes, no arguments, just certainty.

Why do companies still hesitate? Because they think vision systems are expensive, complex or only useful for high-volume production. That’s not true.

- “Too expensive?” With our ROI configurator, you’ll immediately see what a system costs and when it pays for itself. Spoiler: often within a year.

- “Too complicated?” Not when you work with Promation. We guide you from analysis to installation.

- “Not necessary?” Mistakes are costly. Repairs, returns, complaints, downtime… all avoidable with smart vision.

Three smart cameras that make the difference

Cognex offers several In-Sight series, each with different models. We’re highlighting three that are particularly popular with our customers. All of them can be equipped with onboard AI tools. That means they don’t just follow rules, they learn from patterns and adapt to your process. Think of:

- Smart defect detection

- Adaptation to variations

- Continuous improvement

Series 1: Cognex IS2800

The IS2800 is ideal for companies taking their first steps into automated quality control. Think of food manufacturers checking if the expiry date is correctly printed or pharmaceutical companies verifying sealed packaging.

Key benefits:

- Compact size, fits any production line

- Very user-friendly interface

- Quick deployment, no complex software

- Perfect for visual inspection of text, shape, or component presence

- Supports AI tools for pattern recognition and adaptive inspection

Example: a packaging company frequently had incomplete date codes due to a faulty printer. With the IS2800, all dates were visually verified before leaving the line. Result? Significantly fewer errors, saving both time and money.

Series 2: Cognex IS3800

The IS3800 is the next step up, built for higher speeds and more demanding vision tasks. Think of detailed inspections at high throughput.

Key benefits:

- High processing speed for fast lines

- Available in high-resolution models

- Handles complex tasks like inline measurement and defect detection

- Supports AI-driven decision-making

- Ideal for food, cosmetics, and automotive industries

Example: a cosmetics line regularly had products with incorrect labels. The IS3800 verified both the label and cap color, flawlessly, even at 200 units per minute.

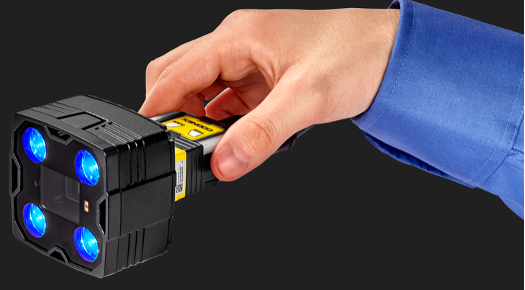

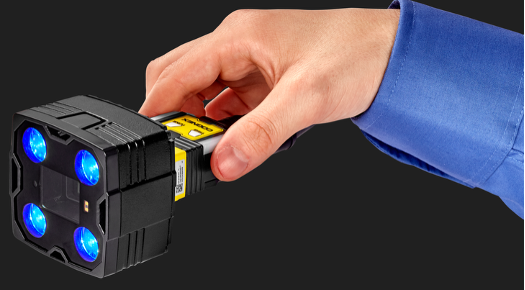

Series 3: Cognex IS8900

No compromises? Go with the IS8900. This Cognex camera offers the performance of the IS3800 in a much more compact format. Perfect for space-constrained applications.

Key benefits:

- High resolution and speed in a compact design

- Advanced image processing

- Suitable for 3D inspection, complex OCR, and robot guidance

- Perfect for compact lines or hard-to-reach areas

- Ideal for applications requiring external lighting

- AI functionality for complex recognition or adaptive processes

Example: a medical device manufacturer used the IS8900 to inspect welds on surgical tools, barely visible to the naked eye, but clearly detected by the camera. Result? Zero-defect production lines.

The ROI of vision systems

A common and valid question: when will I earn this back? That’s why Promation developed an ROI configurator. Based on your production data, it calculates:

- Which camera fits your process

- What the investment entails

- When you’ll start seeing profits

Most of our customers break even within 6 to 12 months. Compare that to other investments on your shop floor. What about integration? Vision systems may seem complex at first glance, but Promation makes it simple:

- We analyze your process together

- We select the right camera, lighting, and setup

- We test and fine-tune on your production line

- We train your team — no IT background required

Vision is more than control, it’s also data. One major advantage often overlooked: cameras collect data. Lots of it. Data that shows where, when, and why issues occur. Even images can be stored, enabling continuous structural improvements.

What else can vision systems do?

Dare to look beyond just visual inspection. Vision systems are often seen purely as quality control tools, but they do much more:

- Robot guidance: camera determines where a robot should pick

- Tracking & tracing: serialization and product tracking

- Process improvement: detect where delays or variations occur in your line

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Time to rethink quality control

We’re no longer in an era where manual inspection is enough. If you want to stay ahead of the competition, you need to produce smarter. Cognex vision systems aren’t gadgets, they’re a strategic investment.

At Promation, we support you with knowledge, experience, and technology. Our ROI configurator shows you exactly what’s in it for you.